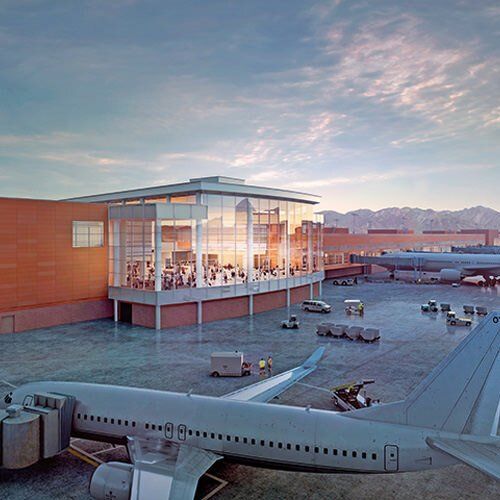

SLC AIRPORT NORTH CONCOURSE EXPANSION PROJECT – PHASE I

Owner: Salt Lake City Airport Authority

Architect: HOK

Engineer: HOK / CEA

Location: Salt Lake City, UT

General Contractor: AOJV-Austin Okland Aviation Joint Venture

Size: 460,000 SqFt.

Completion Date: October 2020

Phase I of this project consists of 460,000 total square feet as follows:

Level 1- operation space, concessions, tenant storage and maintenance; Level 2 - Concourse public space, passenger amenities to include 22 airline gates and hold rooms, public restrooms and a variety of lease space for concessions to include food & beverage spaces; Level 3 – Penthouse Mechanical Rooms for Air Handling Equipment and Indirect Cooling Equipment; Tunnel - Extension of the west midfield passenger tunnel to temporarily connect to the new South Concourse. Included in the tunnel is a mechanical section for the 900-foot extension of the Heating Water and Chiller Water systems from the South Concourse.

The Mechanical system includes a separate Heating & Cooling Plant for the Passenger Boarding Bridges consisting of Chillers, Thermal Storage Tanks and Heat Exchangers. The project is on track to receive LEED Gold certification. Construction is on schedule to complete on an accelerated schedule of October 2020.

SLC AIRPORT TRP EXPANSION – U/G HYDRONIC PIPING PROJECT

Owner: Salt Lake City Airport Authority

Architect: HOK

Engineer: HOK

Location: Salt Lake City, UT

General Contractor: HDJV – Holder I Big-D Joint Venture

Completion Date: October 2019

This project was for the phased installation of the underground Hydronic piping consisting of insulated and jacketed 20” Chilled Water and 12” Heating from the new Central Utility Plant to the Gateway Tunnel for the new Terminal and Concourses. The system was a manufactured fiberglass jacketed insulated epoxy coated piping system. The total length of each of the four piping runs was 1300 feet. The installation involved several steps including excavation, de-watering, welding, 100% x-ray inspection of all welds, joint closures which included: sand blasting, holiday testing, epoxy painting, foam insulation and fiberglass jacket closure. All installation steps included intense QC & QA inspections and documentation. Each phase of the project was completed on schedule.

CORPORATE OFFICE

6761 South Navigator Dr.

West Jordan, Ut. 84084

phone 801.553.9922 fax 801.553.9970

NEVADA OFFICE

4510 B Copper Sage Street

Las Vegas, Nevada 89115

phone 702.644.9350 fax 702.644.9355

All Rights Reserved | J&S Mechanical